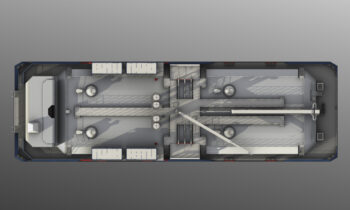

Floating LNG terminal 3 000 m3 SE-607

type:

Low Air Draft Floating Storage and Bunkering Unit (FSBU)

year:

2020

SE – 607 is intended to store LNG and perform LNG bunkering operations, she is non propelled unit without any combustion engines, electric power will be supplied form shore or tug/pusher. FSBU is designed for operation in enclosed waters (harbours). Water ballast used in LNG full load departure condition could be limited to amount necessary for heel/trim adjustment.

Destination of the FSBU shall be as follow:

ReceivingLNG / Discharging LNG prior to maintenance operations in yards,

Cooling down its own LNG cargotanks and cargolines / customer ship’s LNG bunker tank(s)and LNG lines,

Handling vapour return from customer vessel when required,

Discharging LNG to shore storage tank with or without vapour return,

Inerting and purging own cargo handling pipes and LNG bunkering systems by N2 from N2 bottles stored on FSBU in bottle racks.

| Principal characteristics | |

| Length over all: | 65,00 m |

| Breadth moulded: | 19,60 m |

| Depth to main deck: | 6,30 m |

| Design/Max Draught: | 3,00/3,50 m |

| Deadweight at design draught: | 1 450 t |

| LNG capacity: | 3 000 m3 |

| Cargo equipment | |

| Cargo containment: | 4 x 750 m3 bilobe type C |

| Discharging rate: | 1 000 m3/h |

| Discharging pumps (deep well): | 4 x 250 m3/h |

| Class | DNVGL (or other IACS) +1A, RE, Barge For Liquefied Gas, Gas Bunker

PRS *K, III, Barge, Liquefied Gas Tanker |

LNG bunkering vessel SE-606

type:

Low Air Draft bunkering vessel

year:

2019

SE-606 is an enlarged version of our previous design – SE-601. It is a bunkering vessel suitable for supplying various LNG fuelled ships, with 5000m3 tank capacity. Knuckle boom crane, as well as variable operation draught, ensure flexible operation regardless of bunkered vessel type and LNG bunker station arrangement. Two aft azimuth thrusters and forward transversal tunnel thruster guarantee excellent maneuvrability without tug assistance. The flexible cargo handling system is ideal for supplying small scale LNG terminal located on shallow waters. Low air draught allows bunkering operations of LNG fuelled cruise ships and free passing below its lifeboats exceeding the main hull. The vessel is suitable for use as small floating power plant fuelled by LNG and supply electric power to harbor grid.

| Principal characteristics | |

| Length over all: | 99.90 m |

| Breadth moulded: | 16.50 m |

| Depth to main deck: | 7.05 m |

| Design/Max Draught: | 4.50/5.50m |

| Deadweight at design draught: | 2 700 t |

| Service Speed (75%MCR, 15%SM): | 10.00 kn |

| Installed power (Diesel electric): | 2 x 1 400 kWe |

| Cruising range on MDO: | 2 400 NM |

| LNG capacity: | 5 000 m3 |

| Crew: | 10 persons |

| Cargo equipment | |

| Cargo containment: | 2 x 2 500m3 bilobe type C |

| Discharging rate: | 1 000 m3/h |

| Discharging pumps (deep well): | 4 x 500 m3/h |

| Fuel consumptions (LNG/MDO) | |

| At service speed: | 10.2/12.0 t/24 h |

| Optional equipment | |

| Hybrid propulsion system: | 450 kWh |

| Class | DNVGL (or other IACS) +1A, R2 (Baltic), Tanker for liquified gas, Ship type 2G (-163 ºC, 500 kg/m3,0.4 MPa), Gas Bunker, GF, ICE 1B, E0, BIS, CLEAN(DESIGN), RP (2,50), NAUT-AW |

| Download full leaflet | CLICK HERE |

Floating bunkering unit SE-605

type:

LNG Floating Storage/Bunkering Unit (FSBU) 2.000m3

year:

2019

Floating Storage and Bunkering Unit is designated for storing LNG as well as supplying LNG fueled vessels. SE-605 is a barge without propulsion and permanent crew (only operators). FSBU is equipped with bunkering arm for discharging LNG into shore (truck or rail cisterns) or other ships (bunkering operations). Presented barge is a multifunctional platform with a wide range of possible modifications. Depending on customer needs we offer:

FSU (Floating Storage Unit) with tanks capacity up to 3 000 m3 (elongated to 110 m)

FSRU (Floating Storage and Regasification Unit) with containerized regasification units

FPU (Floating Power Unit) with containerized gas-fueled generators

FSPU (Floating Storage and Power Unit) with LNG tank and containerized gas-fueled generators

| Principal characteristics | |

| Length OA | 75 |

| Breadth/Width | 11,4 |

| Draft | 2,5 m |

| Download full leaflet | CLICK HERE |

Hybrid LNG carrier SE-603

type:

arctic LNG carrier

year:

2019

SE-603 is a 10 000 m3 LNG carrier with high ice class ICE-1AS for transport LNG between big and small satellite terminals. Single screw propulsion system with 4 strokes DF engine, reduction gear, and CP propeller, ensure a good balance between investment and operation cost. Two tunnel thrusters, one aft, and second forward, secure high maneuverability when needed. The hybrid propulsion system, with batteries connected to ships electric grid, is shaving load peaks during seagoing and terminal operations, including even zero emission operation. The main engine with PTO or Generating Set operates on optimum load scenario with optimal low fuel consumptions. Optionally, the vessel can be equipped with Yokohama fenders and set of safety features, for Ship to Ship LNG transfer.

| Principal characteristics | |

| Length over all: | 120.50 m |

| Breadth moulded: | 20.80 m |

| Depth to main deck: | 12.25 m |

| Design/Max Draught: | 5.70/6.00 m |

| Deadweight at design draught: | 4 950 t |

| Service Speed (75%MCR, 15%SM): | 15.00 kn |

| Installed power: | 4770 kWe |

| Propulsion battery power | 600 kWh |

| Cruising range on MDO: | 6 100 Nm |

| LNG capacity: | 10 000 m3 |

| Crew: | 16 persons |

| Cargo equipment | |

| Cargo containment: | 2 x 5000 m3 cyl. type C |

| Discharging rate: | 1 000 m3/h |

| Discharging pumps (deep well): | 2 x 500 m3/h |

| Fuel consumptions (LNG/MDO) | |

| At service speed: | 17.2/22.6 t/24 h |

| Optional equipment | |

| LNG Reliquefication Unit/Subcooler Yokohama Fenders | |

| Class | DNVGL (or other IACS) +1A tanker for liquified gas, Ship type 2G (-163 ºC, 500 kg/m3, 0.4 MPa), GF, ICE 1AS, E0, BIS, CLEAN (DESIGN), RP (1,15), NAUT-AW |

| Download full leaflet | CLICK HERE |

LNG bunker vessel SE-602

type:

arctic LNG bunkering vessel

year:

2019

SE-602 is a 7500m3 LNG bunkering vessel with high ice class ICE-1AS for bunkering LNG fueled ships in areas where thick ice level is expected like Baltic and North Seas as well as the coastline of USA and Canada.

Twin screw propulsion arrangement with tunnel thruster forward is ensuring good maneuverability and propulsion system redundancy. SE-602 design is also a good proposal for supply chain between big LNG terminals and small scale local LNG terminals or LNG storage facilities for different purposes. All deck pieces of machinery on exposed to weather deck, including cargo handling system, have the possibility for de-icing using steam.

| Principal characteristics | |

| Length over all: | 109.90 m |

| Breadth moulded: | 18.80 m |

| Depth to main deck: | 10.30 m |

| Design/Max Draught: | 5.70/6.00 m |

| Deadweight at design draught: | 3 800 t |

| Service Speed (75%MCR, 15%SM): | 13.30 kn |

| Installed power: | 2 x 1 660 kW |

| Cruising range on MDO: | 5 500 Nm |

| LNG capacity: | 7 500 m3 |

| Crew: | 16 persons |

| Cargo equipment | |

| Cargo containment: | 2 x 3 750m3 cyl. type C |

| Discharging rate: | 1 000 m3/h |

| Discharging pumps (deep well): | 2 x 500 m3/h |

| Fuel consumptions (LNG/MDO) | |

| At service speed: | 12.1/14.2 t/24 h |

| Optional equipment | |

| LNG Reliquefication Unit/Subcooler | |

| Class | DNVGL (or other IACS) +1A tanker for liquifiedgas, Ship type 2G (-163 ºC, 500 kg/m3, 0.4 MPa),Gas Bunker, GF, ICE 1A*, E0, BIS, CLEAN (DESIGN),RP (2,50), NAUT-AW |

| Download full leaflet | CLICK HERE |

LNG bunker vessel SE-601

type:

Low Air Draft bunkering vessel

year:

2019

SE-601 is a bunkering vessel suitable for supplying various LNG fuelled ships, ideally fits new type cruise vessel with lifeboats that are standing out of the ships line. Knuckle boom crane, as well as variable operation draught, ensure flexible operation regardless bunkered vessel type and LNG bunker station arrangement. Two aft azimuth thrusters and forward transversal tunnel thruster guarantee excellent maneuverability without tug assistance. Flexible cargo handling system is ideal for supplying small scale LNG terminal located on shallow waters.

| Principal characteristics | |

| Length over all: | 81.90 m |

| Breadth moulded: | 16.50 m |

| Depth to main deck: | 7.05 m |

| Design/Max Draught: | 4.00/5.00m |

| Deadweight at design draught: | 1500 t |

| Service Speed (75%MCR, 15%SM): | 10.00 kn |

| Installed power (Diesel electric): | 2×1000 kWe |

| Cruising range on MDO: | 2400 NM |

| LNG capacity: | 3000 m3 |

| Crew: | 10 persons |

| Cargo equipment | |

| Cargo containment: | 2 x 1 500m3 bilobe type C |

| Discharging rate: | 1 000 m3/h |

| Discharging pumps (deep well): | 4 x 250 m3/h |

| Fuel consumptions (LNG/MDO) | |

| At service speed: | 6.8/7.9 t/24 h |

| Optional equipment | |

| Hybrid propulsion system: | 450 kWh |

| Class | DNVGL (or other IACS) +1A, R2 (Baltic), Tanker for liquified gas, Ship type 2G (-163 ºC, 500 kg/m3,0.4 MPa), Gas Bunker, GF, ICE 1B, E0, BIS, CLEAN(DESIGN), RP (2,50), NAUT-AW |

| Download full leaflet | CLICK HERE |